Spring-loaded arms secured by thumb switch grip the tire. Off-center clamping has no effect on accuracy.

Alignment System

Hunter HawkEye Elite®

70-second alignment measurements with pinpoint accuracy makes the HawkEye Elite® the most powerful wheel alignment machine on the market today.

Hunter HawkEye Elite®

/

HawkEye Elite® at-a-glance

Capture alignment measurements in 70 seconds

WinAlign® software is unmatched in the industry

Simplify positioning of market-leading ADAS static calibration fixtures

Easy-clamping, no metal-to-metal contact QuickGrip® adaptors

Configurations built for any shop space

Fully Integrated Alignment rack integration streamlines processes

HunterNet® connectivity to see and manage your performance

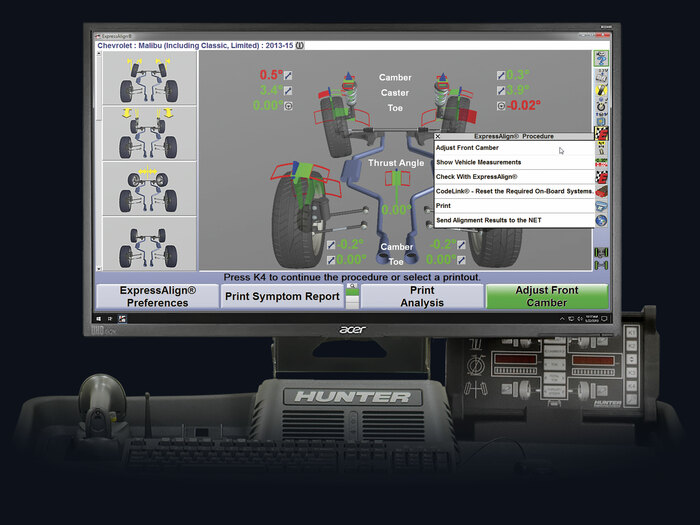

Get alignment results in 70 seconds

Fastest procedure

Only with a HawkEye Elite® can you perform a 70 second alignment check.

Minimal setup effort

One trip around the vehicle means faster alignments.

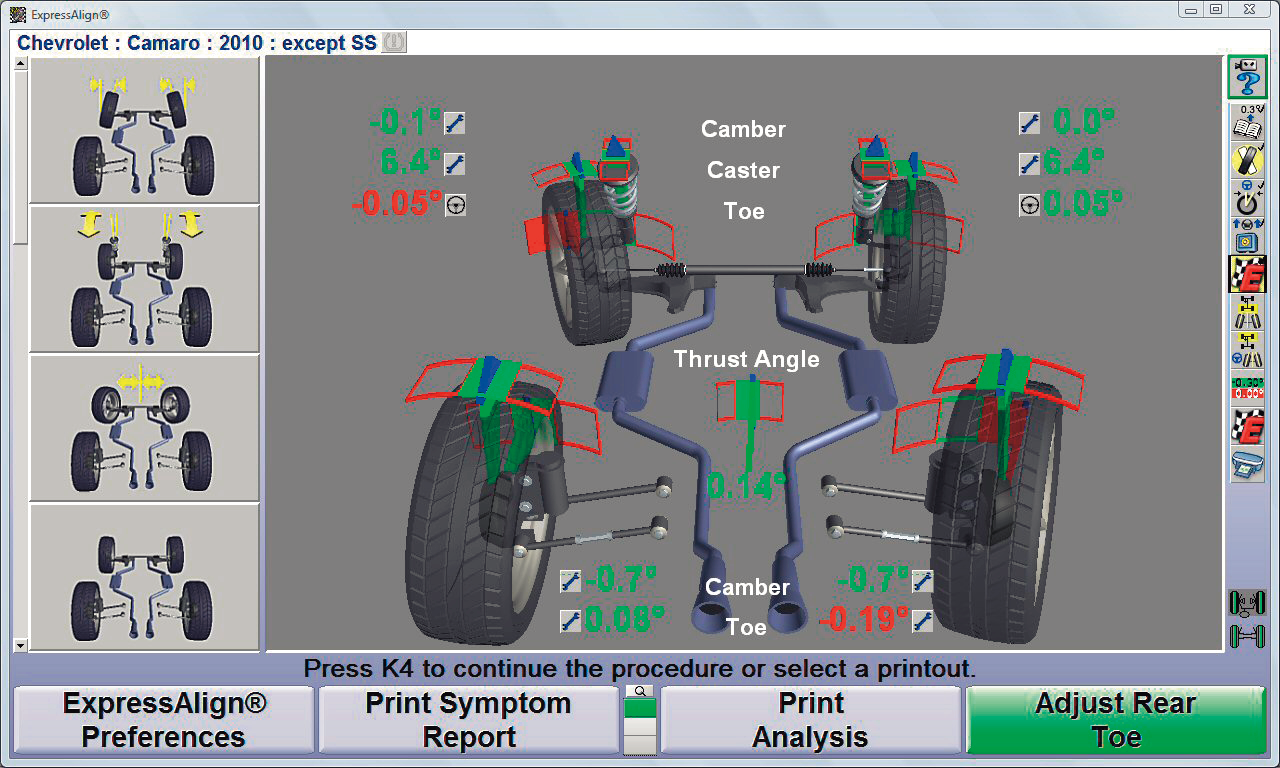

Immediate, accurate measurements

Easy-to-understand graphic representation of camber, toe and caster.

Define the standard with Hawkeye Elite® + WinAlign®

With 70,000 systems in use worldwide and a database supporting more than 285 million vehicles, HawkEye Elite® and WinAlign® have long defined the performance standard for alignment equipment past, present and future.

70 Second Alignment Drill

Watch how a fully-comprehensive wheel alignment check can be done in just over a minute.

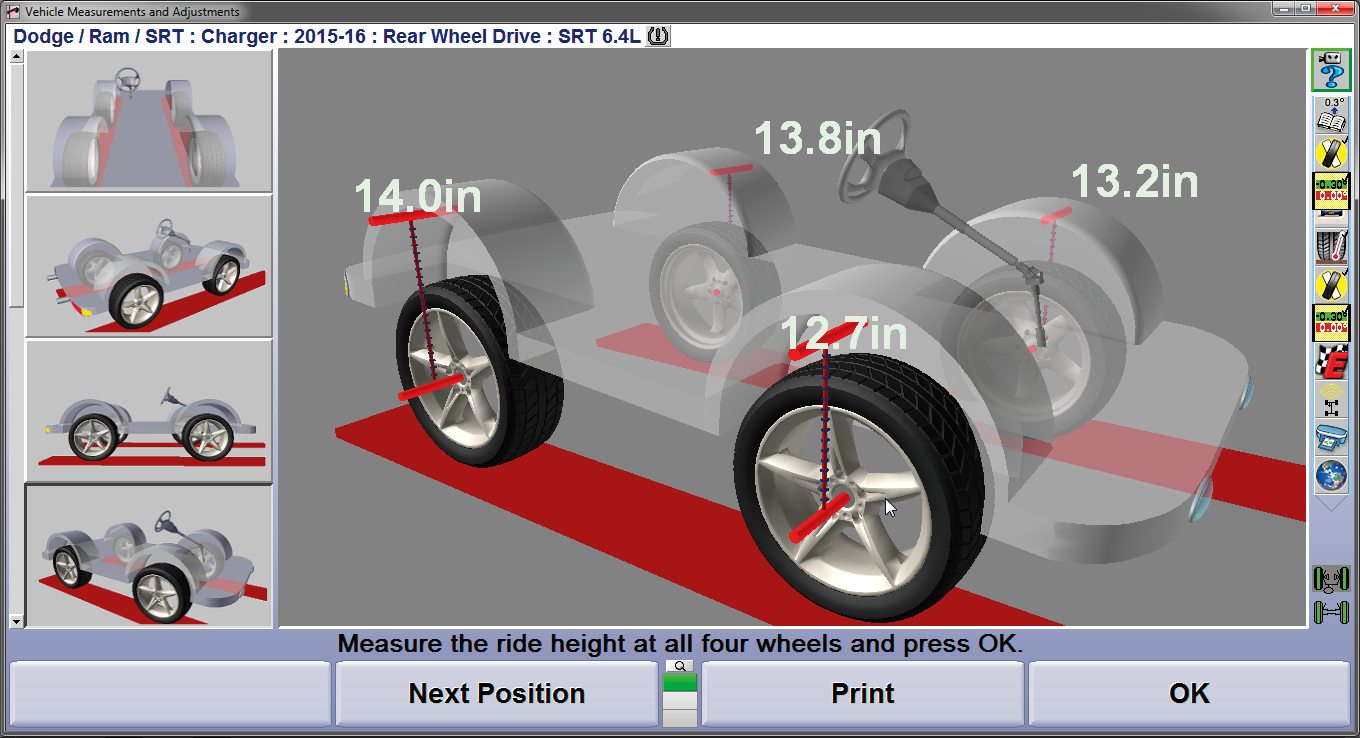

Why Do Cars Need Wheel Alignment?

When your car is out of alignment, you may experience irregular tire wear, handling problems or a crooked steering wheel. A wheel alignment adjustment can correct these problems.

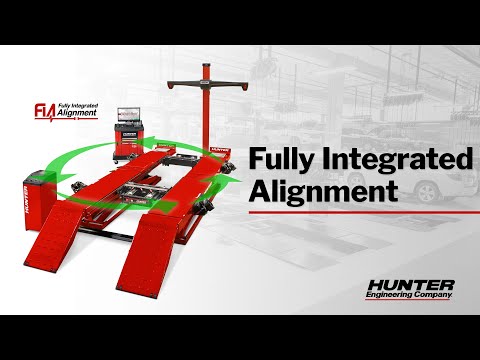

Fully Integrated Alignment Equipment from Hunter Engineering

Hunter's fully integrated alignment system reduces the technician's trips around the vehicle, and greatly reduces trips to the alignment console.

Calculate your payoff and profits

Speed setup time with Hunter's patented QuickGrip® adaptors and 3D targets

Fast installation

Spring-loaded clamping arms install easily — off-center placement has no affect on accuracy.

Avoid rim damage

Clamps hook tires and protective ring provides no metal-to-metal contact.

Efficient design

Lightweight, durable and low-profile form make QuickGrip® adaptors a technician-favorite.

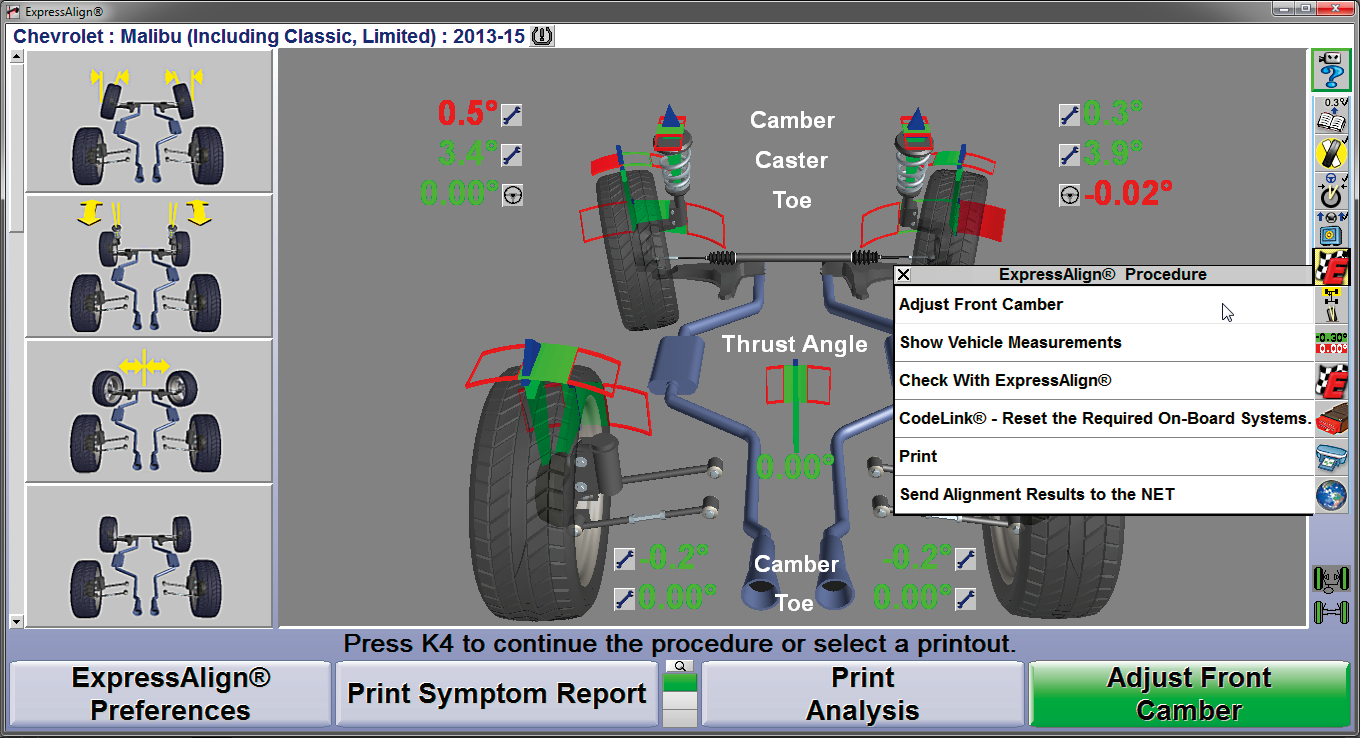

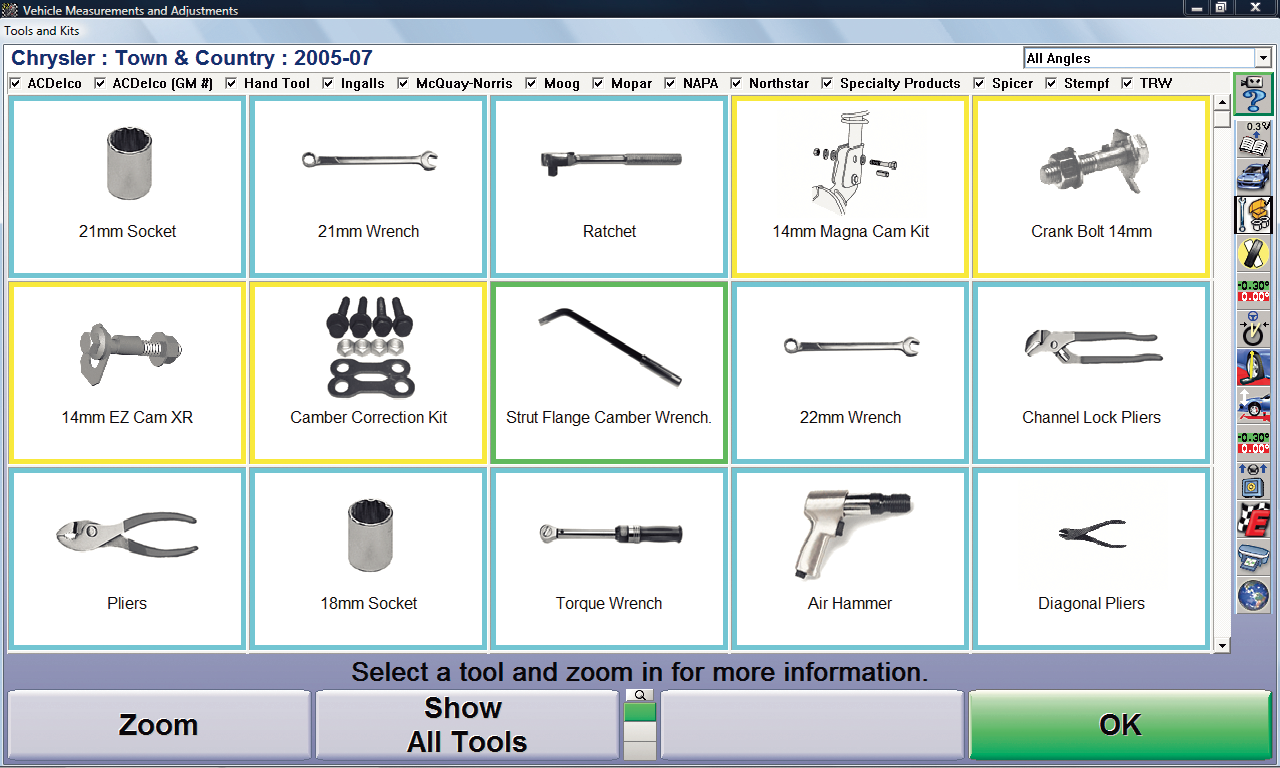

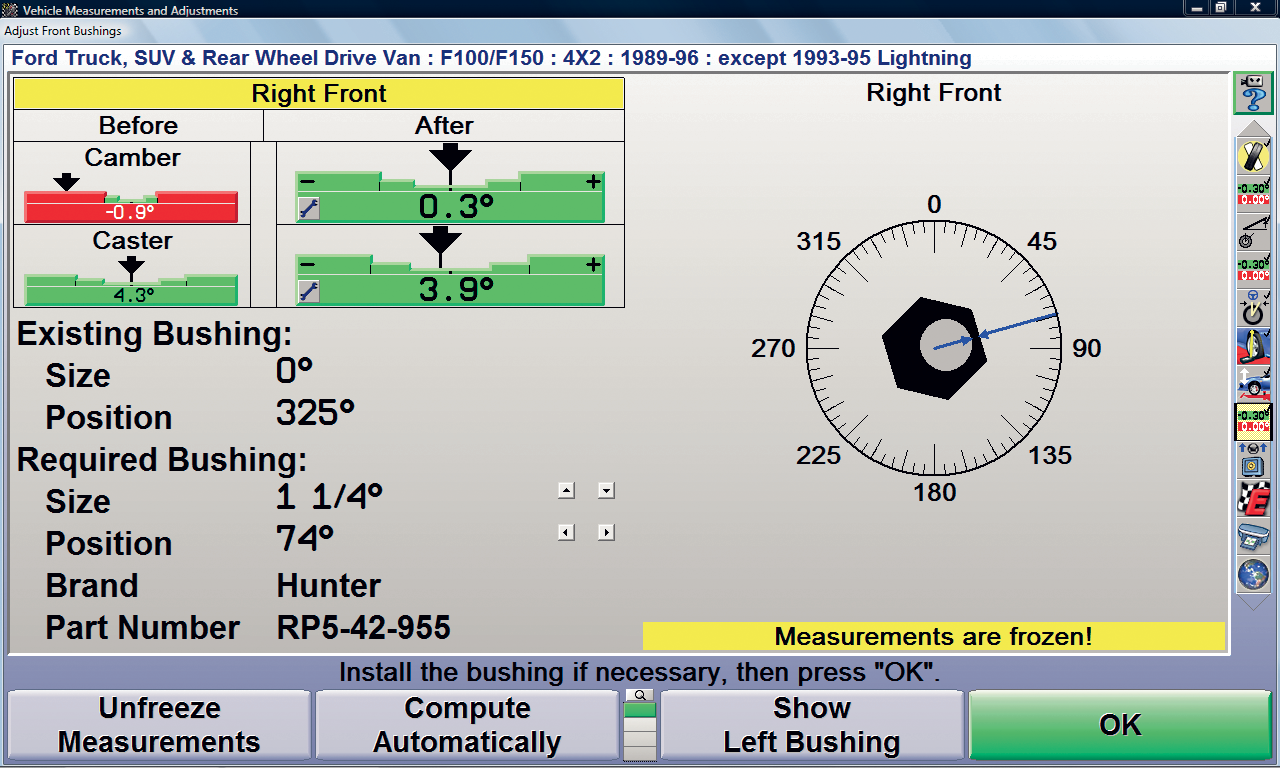

Align accurately the first time using Hunter's award-winning WinAlign® software

Extensive Database

WinAlign® is powered by the most extensive vehicle information use, 285+ million vehicles supported.

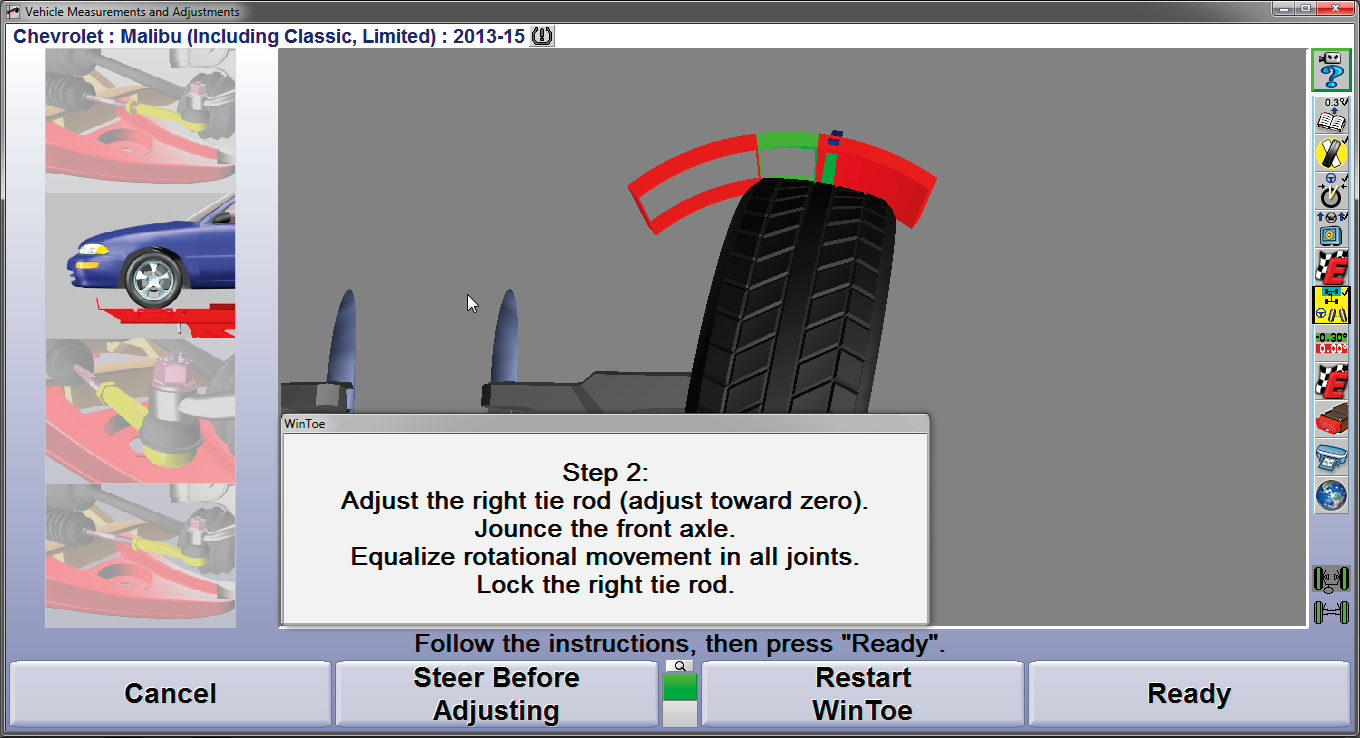

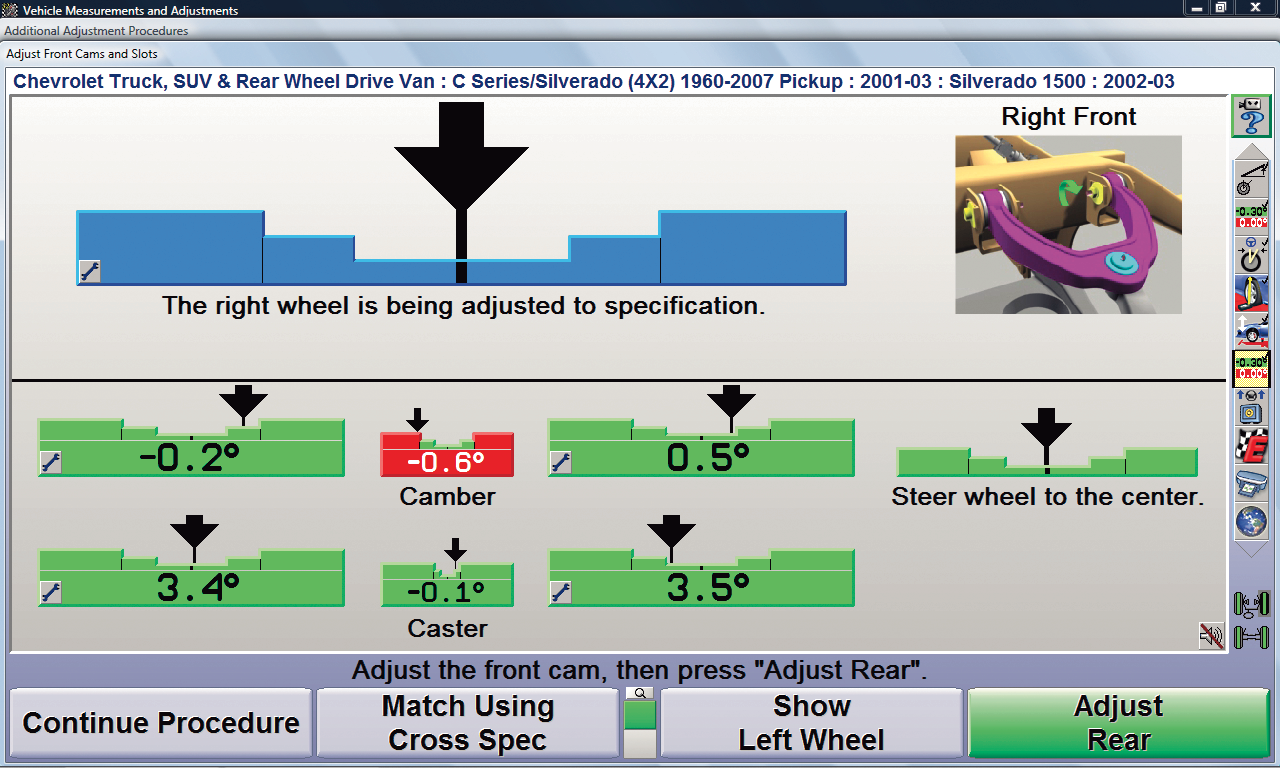

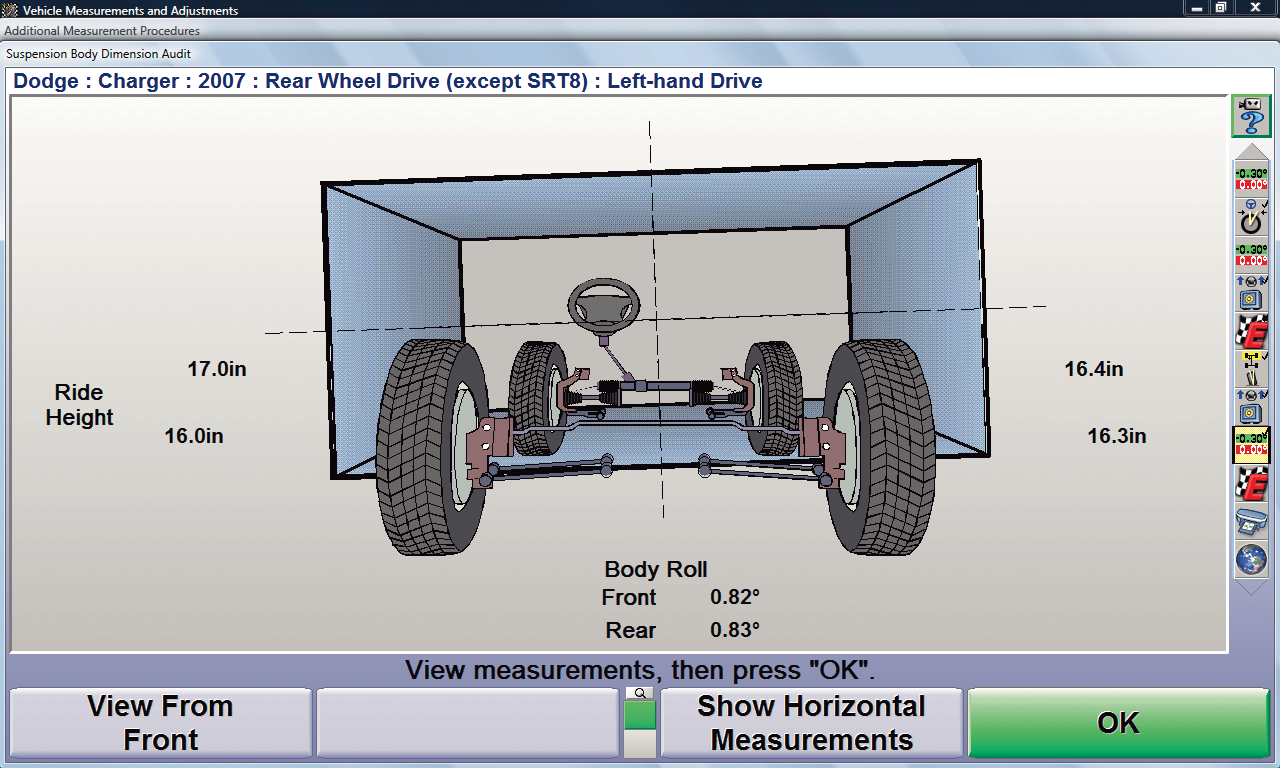

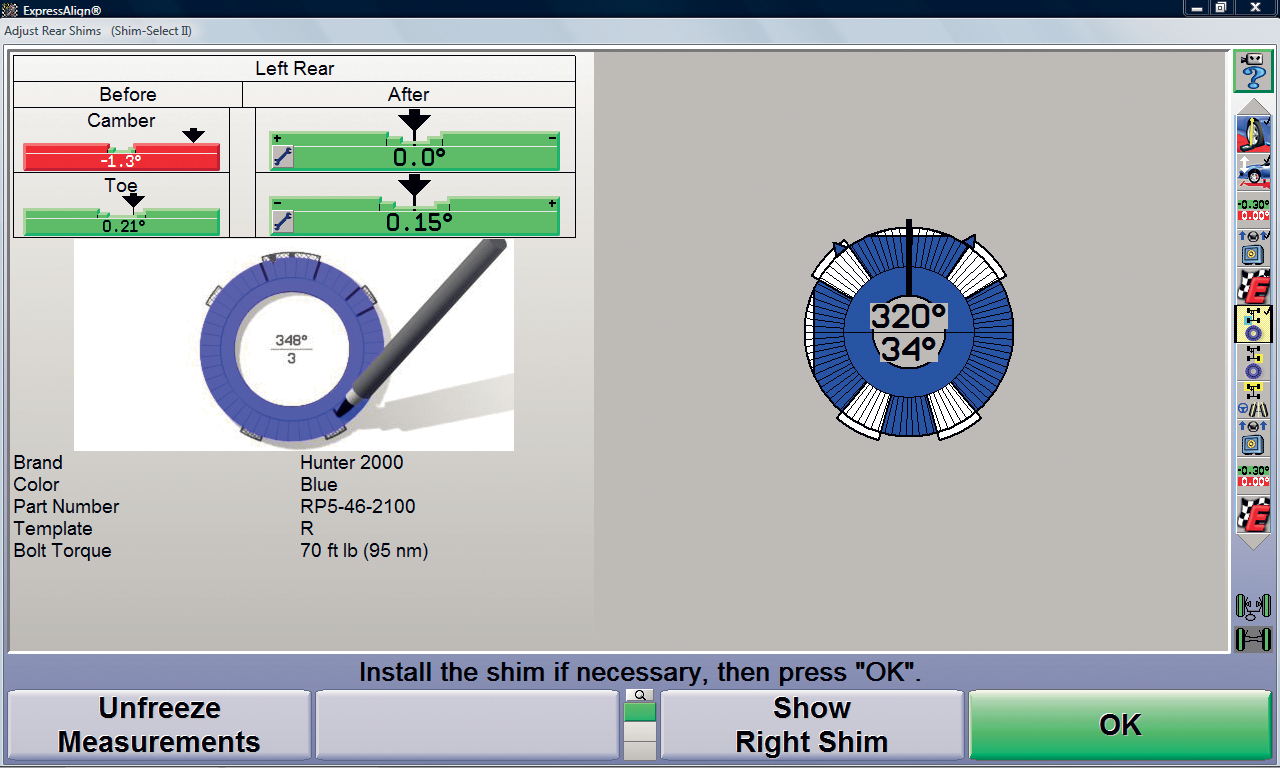

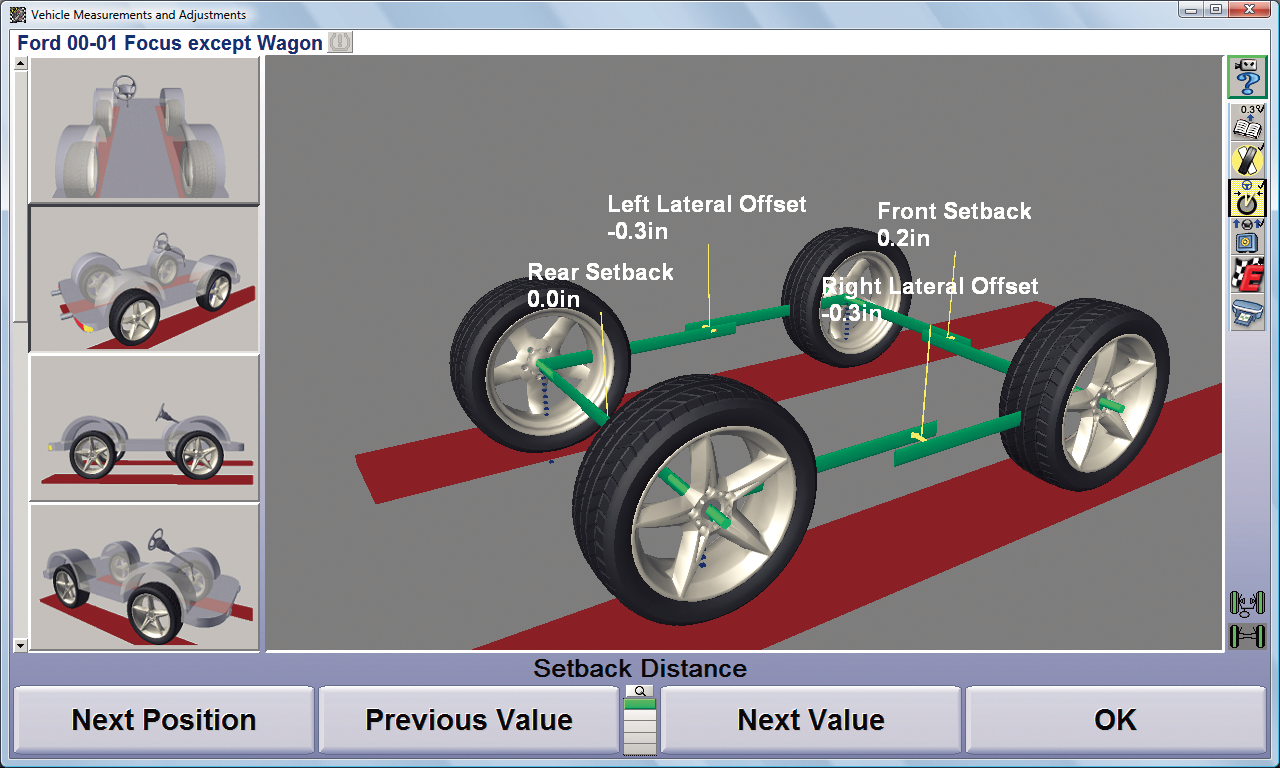

Vehicle-specific procedures

Guide your technicians with step-by-step instructions specific to the vehicle being serviced.

Over 30 years of development

Constant improvements and support come from the largest R&D department in the undercar industry.

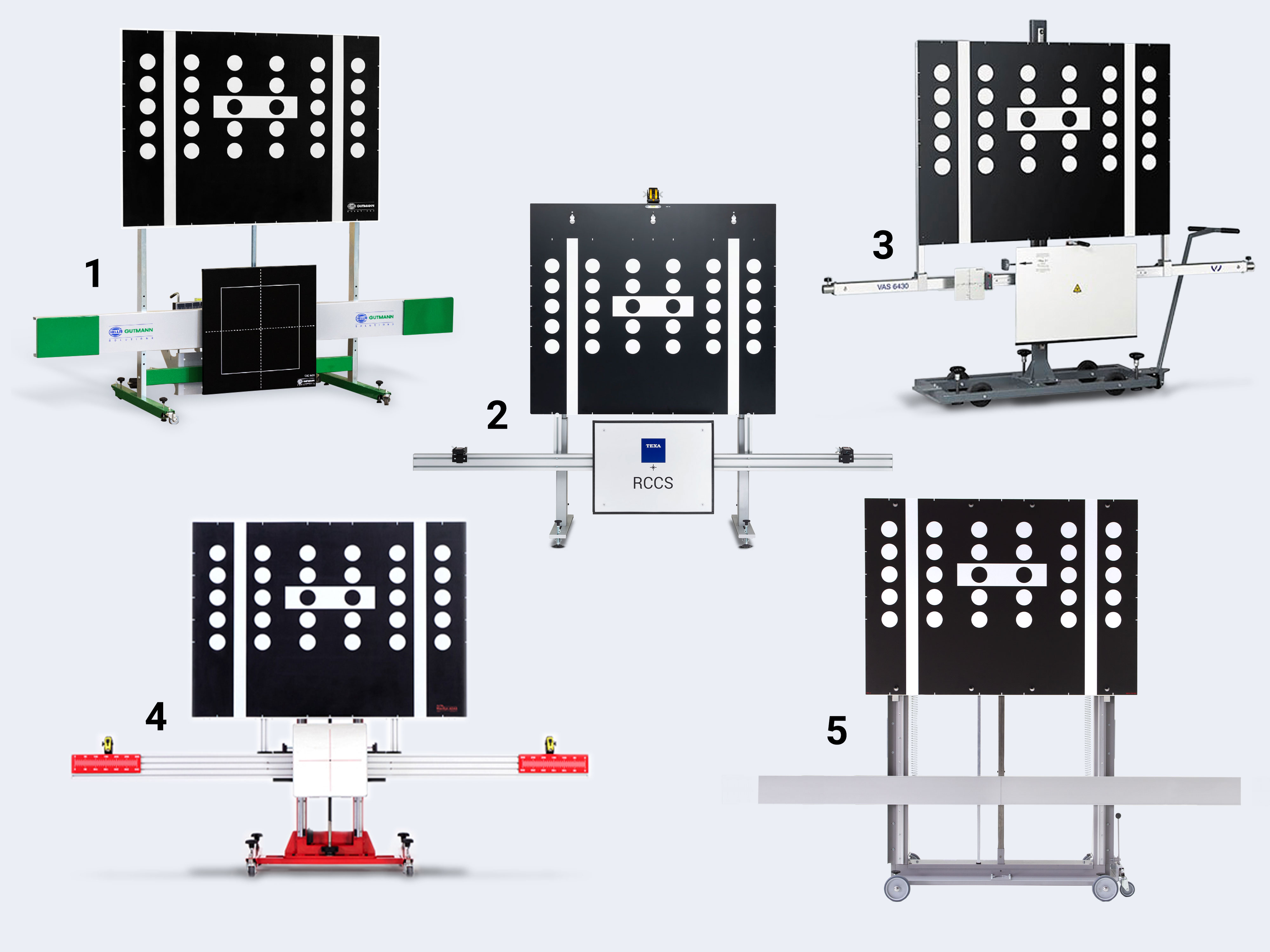

Simplify positioning of market leading fixtures by using Hunter cameras

ADAS alignment setup is fast, efficient and accurate

- 50% faster fixture positioning

- Eliminates potential for wheel damage

- Accurately position fixture to vehicle thrustline using cameras

Shown with Hella Gutmann ADAS calibration fixture.

Choose the ADAS Fixture that best covers your workshop

- Hella Gutmann

- Texa

- OEM

- Autel

- WOW!

Fixtures require Hunter camera kit and adaptors.

Alignment machines built to fit your workspace

Options for every shop

Alignment console and sensor combinations to suit every need.

Sensors fit any space

Regardless of bay or space constraints, Hunter has a sensor package designed to fit.

Productive console designs

Award-winning WinAlign® software delivers dozens of productivity tools in a console to fit your needs.

Mobility and space-saving

Cabinet-mounted configuration is mobile to service multiple alignment bays and provides a manual lift camera adjustment for a wide range of lift heights.

Full-range height

Motorized and manual movable-camera configurations provide a full range of vertical travel for additional lift height.

Open-floor area

Wall- and ceiling-mount configurations are perfect when space is at a premium.

Compact fit

Fixed column camera configurations fit most service bay applications.

Large console

Maximum storage space and convenient mobility

Compact console

Mobile console unit for tighter spaces

Wall-mounted console

The most compact configuration — mount to wall or sensor column

Streamline the process with Fully Integrated Alignment (FIA)

60% Faster

Complete alignments faster with Hunter's synchronized wheel alignment machine and alignment rack.

Automatic Functions

Turnplates and slip plates auto-lock, and inflation station automatically inflates tires.

Eliminate Errors

Automates technician tasks that can be easily forgotten or skipped.

Precision Cameras

- Four high-resolution cameras

- Measurements are taken automatically once the fourth target is installed

WinAlign® Console

- Guides the technician through the alignment process

- Centralized control of entire system

- Communicate directly with lift to set tire pressure and automatically operate turnplates and slipplates

Auto-locking turnplates & slipplates

Auto-lock saves time and trips around the vehicle

Inflation Station

Patented

- Automatically inflates all four tires simultaneously

- Automatically records starting and final pressures

- Hose recoils to keep work area clear

PowerSlide® System

Patended

- Slipplates and turnplates automatically lock and unlock at appropriate times

- No more struggles with turnplate & slipplate pins

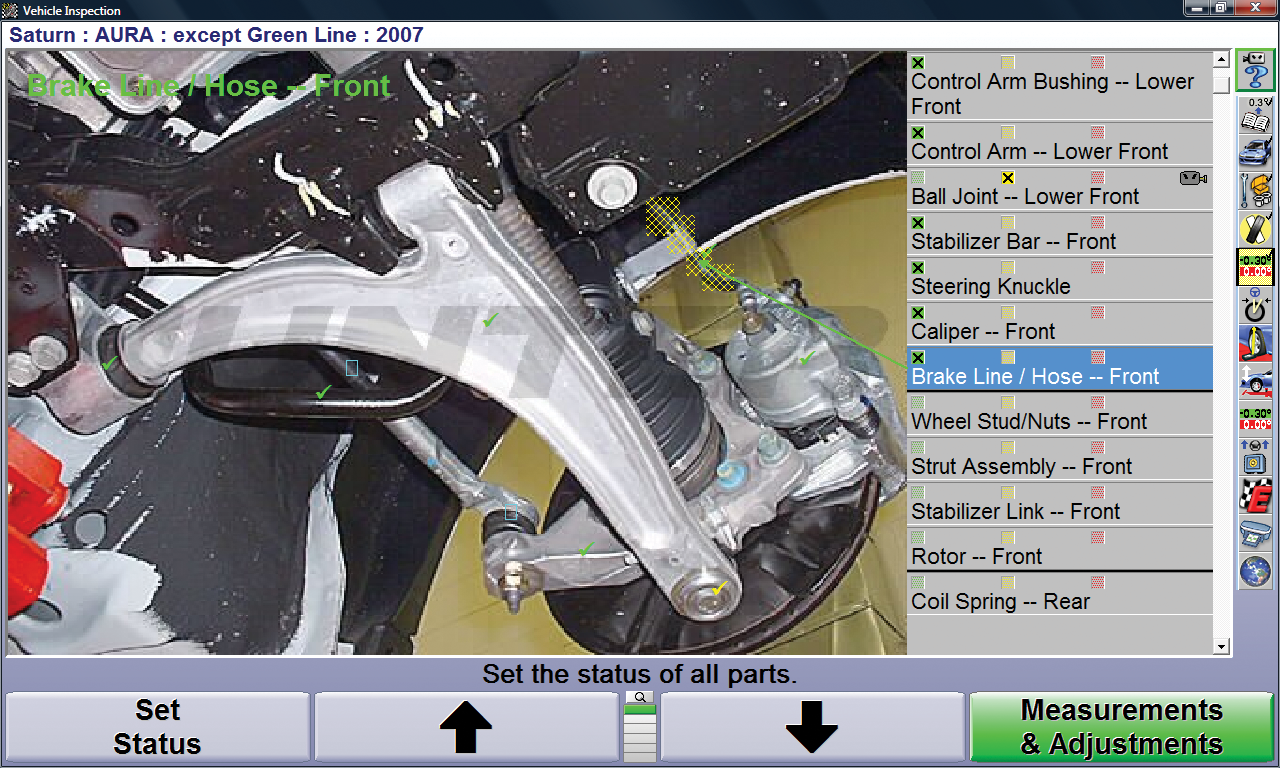

Access vehicle-specific undercar information in the alignment bay

- Explore a vast collection of vehicle-specific undercar information

- Eliminate time-consuming manual searches with our online database of advanced sensor reset requirements

- See how-to's and instructions featuring illustrations, images and videos

Improve communication all around

Communicate results & educate your customers on misalignment, while accessing vehicle-specific undercar information in the alignment bay with WebSpecs®.

Connect your equipment to your business

- Maximize your shop's performance

- Simplify customer discussions with selling tools

- View extensive undercar information

Monitor Trends

Get a high-level overview of your alignment machine usage trends.

Receive daily reports

Setup to receive daily Push Reports to keep your goals and performance in check.

Recall Past Results

View previously serviced vehicles and recall printouts.

Gallery

Because of continuing technological advances, features and configurations shown in customer photos may vary.

Documents

-

Brochures

-

Specifications

-

Accessories

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

From raw steel to finished product. When you choose Hunter, you're investing in more than 1,000 American workers.